Frustrated by Equipment Failures and Maintenance Costs?

Experience the Peace of Mind That Comes with Makurung's Proactive, Data-Driven Approach to Process Optimisation

Request your FREE On-Site Assessment today and let Makurung's expert engineers conduct a thorough inspection of your spiral plant, flotation process, or grinding mill.

Maximise Uptime, Minimise Costs with your Free On-Site Assessment

At Makurung, we understand the critical impact unplanned downtime can have on your mining operations. To help you combat this challenge, we're offering a complimentary on-site assessment conducted by our seasoned engineers.

What the Assessment Includes:

Thorough Inspection

A detailed examination of your spiral plant, flotation process, or grinding mill setup, with a focus on identifying potential areas of weakness or inefficiency.

Data Collection

We'll gather relevant operational data to identify patterns and trends that may be contributing to downtime.

Expert Analysis

Our experienced engineers will meticulously analyse the collected data and on-site observations to pinpoint the root causes of downtime events.

Customised Recommendations

You'll receive a tailored action plan outlining specific measures to prevent future breakdowns, optimise performance, and extend equipment lifespan.

Cost-Saving Strategies

We'll identify potential cost-saving opportunities through improved maintenance practices, process optimisations, and equipment upgrades.

Condition Monitoring System

Our advanced system utilises real-time data and analysis to predict the lifespan of flotation wet ends spares and mill liners, helping you proactively avoid costly failures.

Maximise Uptime, Minimise Costs with your Free On-Site Assessment

At Makurung, we understand the critical impact unplanned downtime can have on your mining operations. To help you combat this challenge, we're offering a complimentary on-site assessment conducted by our seasoned engineers.

What the Assessment Includes:

Thorough Inspection:

A detailed examination of your spiral plant, flotation process, or grinding mill setup, with a focus on identifying potential areas of weakness or inefficiency.

Data Collection:

We'll gather relevant operational data to identify patterns and trends that may be contributing to downtime.

Expert Analysis:

Our experienced engineers will meticulously analyse the collected data and on-site observations to pinpoint the root causes of downtime events.

Customised Recommendations:

You'll receive a tailored action plan outlining specific measures to prevent future breakdowns, optimise performance, and extend equipment lifespan.

Cost-Saving Strategies:

We'll identify potential cost-saving opportunities through improved maintenance practices, process optimisations, and equipment upgrades.

Condition Monitoring System:

Our advanced system utilises real-time data and analysis to predict the lifespan of flotation wet ends spares and mill liners, helping you proactively avoid costly failures.

The Hidden Costs of Downtime: Is Your Mining Operation Bleeding Money?

Unplanned downtime isn't just an inconvenience in South African mining - it's a financial nightmare. Every idle minute translates to lost profits, missed deadlines, and mounting stress. The constant battle against equipment failures, inefficiencies, and skyrocketing maintenance costs leaves you feeling trapped in a reactive cycle.

The financial toll is immense. Studies estimate downtime can cost up to R1.8 million per hour, impacting your bottom line and the broader economy. But imagine a different reality: proactive maintenance, optimized processes, and predictable equipment lifespans.

Break the Cycle: Makurung's Proactive Approach to Process Optimisation

We understand that reactive maintenance is a losing battle. That's why we offer a proactive, data-driven approach to tackle the root causes of downtime and inefficiency. Our comprehensive suite of services, including:

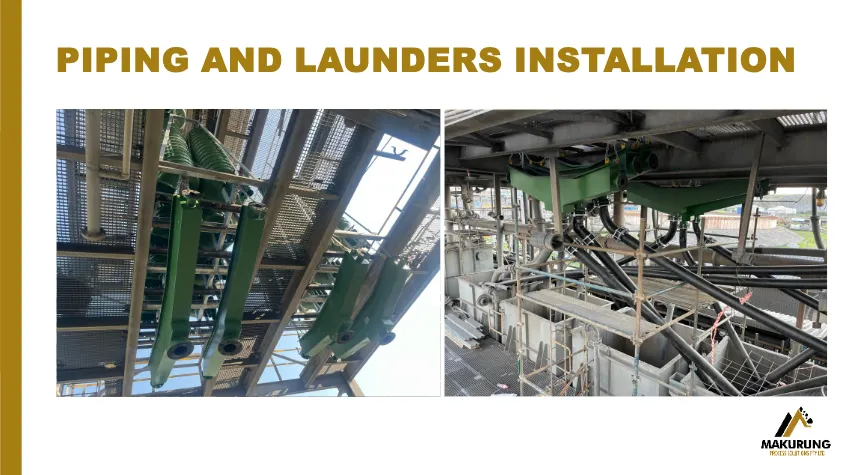

Spiral Plant Design, Construction, Maintenance, and Optimisation:

From tailor-made solutions to turnkey chrome washing plants, we ensure your spiral plant operates at maximum efficiency, boosting recovery rates and minimising water consumption.

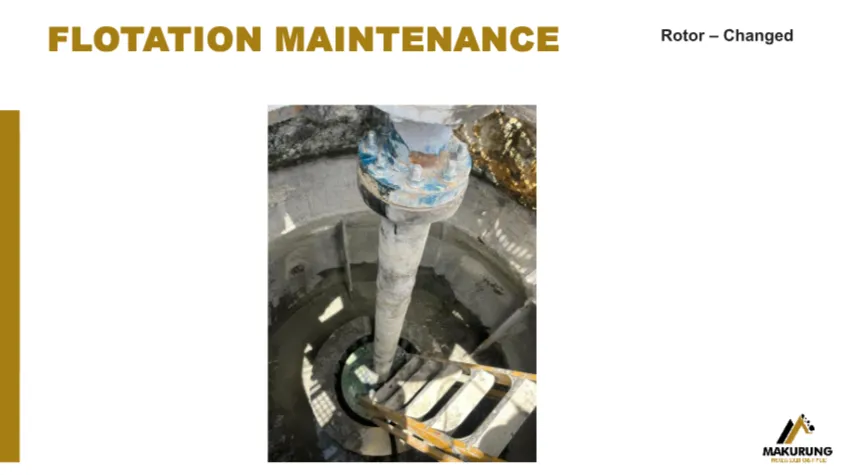

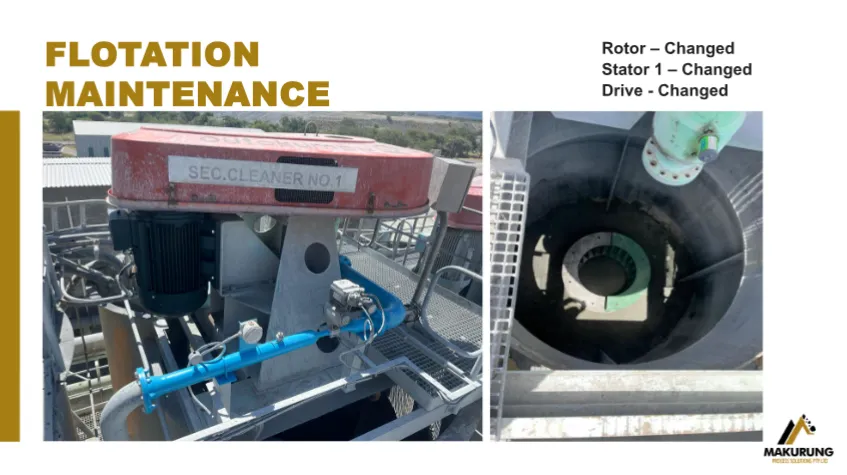

Flotation Maintenance and Optimisation:

Our expert inspections and real-time condition monitoring system predict lifespan and prevent failures, keeping your flotation process running smoothly and maximising mineral recovery.

Mill Relining:

We optimise mill liner selection and replacement schedules, minimising downtime and ensuring optimal grinding efficiency to reduce energy consumption and enhance throughput.

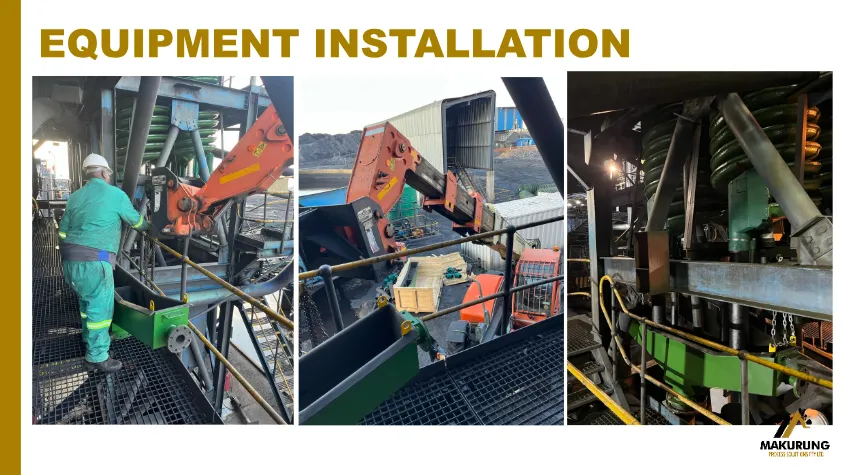

Some Of Our Client Work

Minopex Baobab Shaft

Nndanganeni Coal Mine

Tharisa (Arxo Metals)

Some Of Our Client Work